This topic comes up a lot on gun forums. Someone will ask, "I have been thinking about getting an AR-15. What should I get?" and someone will answer, “Build one yourself.” Even though that sounds like a great idea, it may not be the best advice to give someone, not knowing their skill level and familiarity with AR15s or if they even have space to build one.

Why should I buy an AR15-style MSR rather than build one?

For those without the workspace tools and time, finding the best-built MSR to suit your purpose might be a better option. MSRs come in a variety of configurations. They are built by factory-trained workers, and some are even factory-tested. They often come with warranties and carry the brand's reputation. Some brands will hold a better resale value than selling a "parts gun." One can always customize after the purchase to suit their purposes as they go, which may be a better option for many.

Why build an AR15-style MSR when I can buy one?

There are many great reasons to build your AR-15-style rifle besides the satisfaction of building one yourself. The AR-15 is easy to assemble if one knows how it goes together and operates. If one has the right tools and workspace to build it, they can build the exact rifle they desire for the shooting they do and possibly save some money, too.

It may be best to have a built AR-15 to refer to. Remember, you are assembling a firearm, and safety first. Many will buy their first one complete and then upgrade the parts, learning how everything goes together and operates, and then build one. Building your own AR-15-style rifle can become an addictive hobby. If you have a friend who has built one or watched videos, that helps, too. It’s not hard, but it has to be done right if you want it to work and function safely.

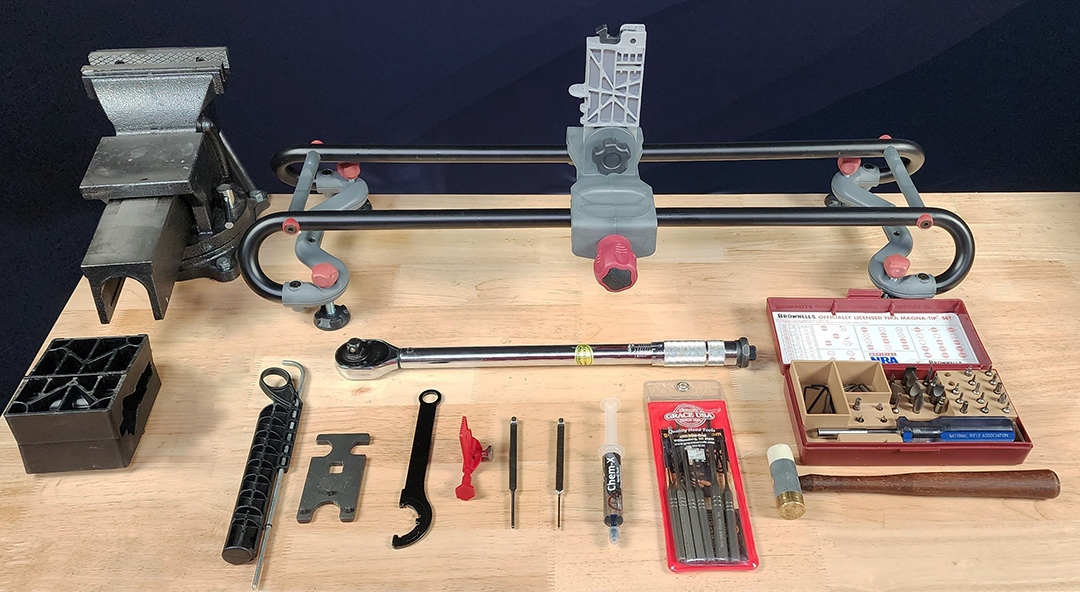

Tools needed to build an AR-15 style rifle.

To build an MSR, you need a vice, a torque wrench, a barrel nut wrench, a small hammer, roll pin punches, an action block or a reaction rod, and eye protection. Some special tools are not needed but will make it a lot easier, like a take-down pin installation tool, slave pins for the hammer and trigger, a gas tube alignment tool, and a gas block dimple tool.

Building a purpose-built AR-15-style MSR.

One may not find the exact rifle with all the features they want prebuilt, so they end up paying for parts they didn't want. A purpose-built rifle means that the builder has a specific purpose for the rifle. They may want something short-range for tactical purposes and build it to shoot 9mm instead of 5.56. They may prefer M-LOK over a Picatinny rail to attach a light. There are several stock options, from fixed to collapsible. There are also many different kinds of forward controls to choose from, depending on the end purpose, as well as many cartridge options to suit different purposes.

Or a shooter might build one as a long-range tack driver using a longer premium barrel and fixed stock. Shooters participating in speed competitions will want parts that increase speed because most competitors are timed. Also, there are color options other than black to personalize an MSR.

Barrels come in different qualities, thicknesses, and materials and can cost a lot of money for a really accurate or long-lasting one. However, there are plenty out there that are affordable and good enough for plinking and target practice.

AR15 barrels come in different lengths for different kinds of sport shooting but keep this in mind: There are strict laws with severe penalties regarding the minimum barrel length on a rifle. So, before you start buying parts, research your state and federal laws regarding minimum barrel length as well as certain features that may not be legal for the build you want to build.

Building an AR-15 Style MSR can save you money

Many upgrades are available for MSRs. A shooter may wish to install a specific trigger, such as a 2-stage or drop-in competition trigger. They may wish to install a Picatinny rail, a M-LOK, a Keymod, or a retro plastic handguard.

Building your own allows one to go cheap on parts that may not be as important as others. One might be able to save money on the upper and lower receivers and spend that money on a better trigger or quality scope mount for their AR-15. Also, building it oneself is like a layaway program; one can buy parts as they can afford them and assemble the MSR over several months. There are gun forum classifieds where a gun hobbyist can save money by buying good used parts.

However, if a first-time builder gets a box of parts and has no idea how it all goes together to function correctly, they may skip something important, like proper torque on the barrel nut.

AR15 Trouble Shooting Guide

Common mistakes beginners make while building their first AR15-style rifle.

- A gas tube installed backward or not pinned correctly – causing the rifle to be a single shot.

- A backward hammer spring - the gun sometimes fires, mostly light primer strikes.

- If the gas tube is installed crooked, it can cause the bolt carrier group to bind, causing feed issues and gas issues. A lot of problems can be caused if the gas tube is not installed correctly.

- The upside-down disconnector spring is causing a trigger reset issue.

- Loose barrel nut - accuracy issues and, depending on how loose, could be dangerous to shoot.

- The buffer retainer spring is not installed correctly, causing the buffer to stick out and making it difficult to close the upper to the lower.

- Misaligned gas block to gas port - causing failure to cycle or failure to feed.

- Loose gas block, not dimpled, causing it to move out of port alignment – won’t cycle.

- Forgetting to lube new parts, causing malfunctions and sluggish operation.

- Install incorrect parts – for example, using a wrong buffer spring, wrong length buffer, or a buffer that is too heavy or too light.

- Gas Key Leak from the gas key not torqued and staked.

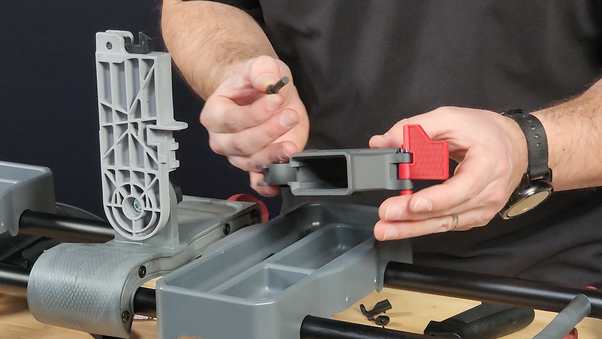

Be sure to wear eye protection when assembling an AR15 because you can injure an eye while installing spring-loaded detents. A couple of different tools are made for installing the detent in the front takedown pin, which makes the task easier. There are ways to install them without the special tool, but it's best to have a couple of spare detents in case one shoots out while installing and gets lost.

After the rifle is built, it's time to choose what kind of sight or optic you are going to use, be it iron sights or an optic, depending on your budget and the shooting you plan on doing. If you decide on a red dot reflex optic, check out Warne's Red Dot Risers. If you plan or use an LPVO or other magnified scope.

Choosing the correct optic or sight for your MSR is another topic as there are so many options out there. Some may want to go with open sights, and there are many options of open sights, from the detachable carry handle to flip back up iron’s sights or side mounted sights. A lot shooters who build MSRs are looking for precision or speed. When looking for precision, a Shooter will usually go with a magnified optic and when looking for speed a red dot optic or if they are going for both they may get a magnified optic and with a red dot mounted on a 45-degree mount like the photo above or an LPVO which combines both with some limitations read more about LPVO vs Red Dot and read more about what MSR Mounts Warne offers to keep you target. Read about the best scope mounts for AR15 style rifles.