7244M Warne Mountain Tech 35mm, Ultra High Matte Rings

$169.99

- SKU:

- 7244M

- Brand:

-

Mountain Tech®

- Lightweight.

- Mil-Spec Hardcoat.

- Stainless Steel Hardware.

Description

Available in 1, 30mm,34mm, 35mm and 40mm size.

Designed and MADE IN USA

Lightweight and element proof We engineered Warne Mountain Tech as a lightweight and rugged scope ring design that is equally at home on a mountain rifle or precision target rifle. Featuring 7075 aluminum construction and stainless hardware to withstand the punishing conditions Mother Nature can dish out.

- Precision CNC machined from 7075/T6 aluminum for a high strength & lightweight platform

- Mil-Spec hardcoat anodized finish for abrasion and corrosion resistance.

- Rings feature stainless steel hardware for "Element Proof" protection.

- Mil-Spec 65 in/lb., 1/2" tactical nut attachments for securely clamping to the rail.

- Fits Picatinny & we'ver style mounts and are NATO-STANAG compatible.

- Available for 1", 30mm , 34mm, 35mm and 40mm tube sizes; in Low, Medium, High and MSR ideal height; For maximum compatibility with most scope/firearm combinations.

Specifications

- Part Number:

- 7244M

- Fits Objective Size:

- 72mm

- Height:

- Ultra High

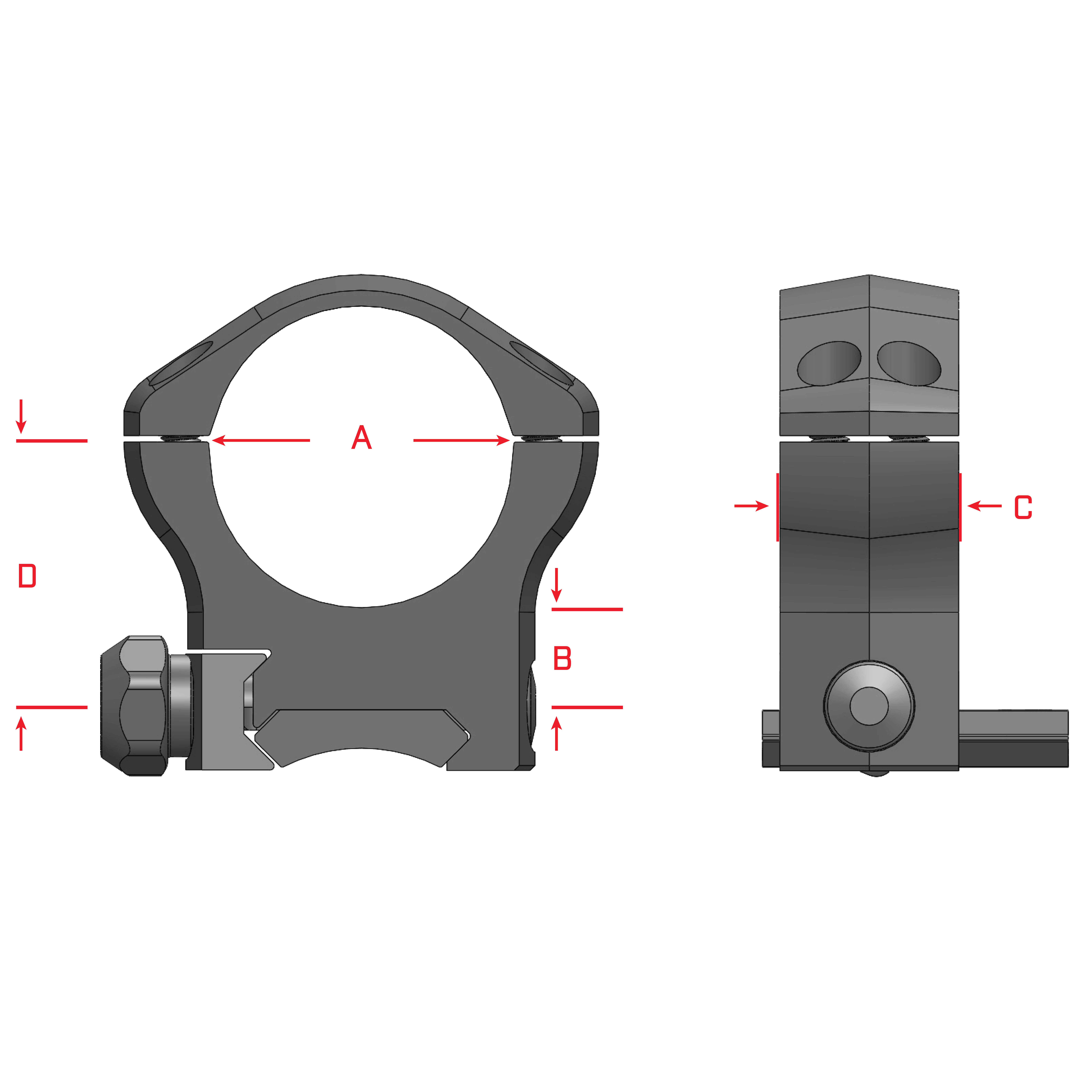

- Dimension A:

- 35mm

- Dimension B:

- 0.750 inch

- Dimension C:

- 0.705 inch

- Finish Color:

- Matte Black

- Weight:

- 5.1 oz

- Material:

- 7075 Aluminum

- Fits Objective Up To:

- MSR Ideal Height

- Scope Tube Diameter:

- 35mm

- Fits:

- Maxima/Weaver Bases and Picatinny Rails

Installation Instructions

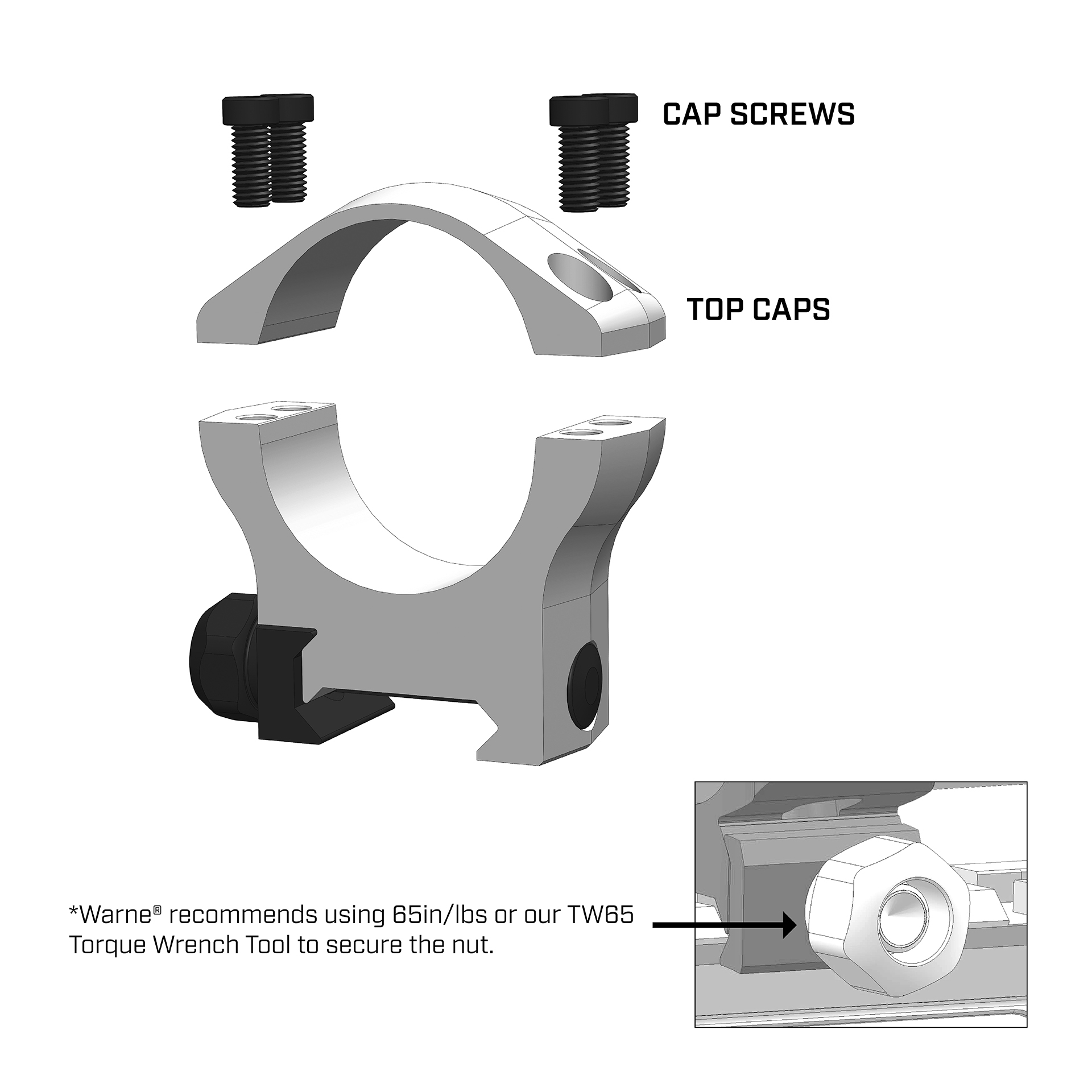

Always verify that your firearm is UN-LOADED before performing any service on it. Warne recommends that you loosely assemble rings and scope onto firearm prior to final mounting to verify eye relief and ring spacing.

- Loosen both nuts on the Mountain Tech rings and install on your Mountain Tech rail or Maxima (weaver style) bases.

- Slide each ring forward so the recoil lug is contacting the front of the cross slot. Torque the ring nut to 65 in/lbs maximum and repeat for the other ring.

- Remove the four cap screws from each top cap with the supplied T-15 wrench and remove top caps.

- Place your scope in the Mountain Tech rings and replace top caps and screws*

*Torque Spec are for dry threads, DO NOT USE THREAD-LOCKER COMPOUND

**Many scope manufacturers’ have established specific torque ratings for their scope and you must follow their recommended torque.

To remove the scope, simply loosen the ½” nut and lift the scope off the mount, tilting slightly to the opposite side of the nut. To re-mount the scope, simply place the rings into the slots the scope was originally mounted in, slide the rings and scope forward until the recoil lugs contact the front of the slot, and tighten the ½” nut. NOTE: The ½” tactical nut screw assembly is pre-set at the factory and does not require any adjustments. Tampering with this screw can cause improper function of the scope rings.IMPORTANT: NEVER OVER TIGHTEN ANY BASE OR RING SCREW. NEVER ATTACH A SCOPE IF THE OBJECTIVE TOUCHES THE BARREL OR CAUSES INTERFERENCE WITH THE BOLT, SAFETY OR CYCLING OF THE ACTION. ALWAYS FOLLOW THE FIREARM OR SCOPE MANUFACTURERS’ RECOMMENDED TORQUE SPECIFICATIONS. YOU ARE RESPONSIBLE FOR YOUR OWN GUNSMITHING METHODS.

If you are unsure or do not have the proper tools, please contact a gunsmith for assistance, Warne will not be held liable for stripped/damaged receivers or scopes.